PARAT IEH

High Voltage Electrode boiler for Steam and Hot water

- High-Pressure Steam up to 85 barg

- Zero-Load

- Combined Hot Water & Steam in one unit

- From cold to full load in less than 5 minutes

- 30 seconds from minimum to full load

- No earth current

- Compact design – up to 75 MW in one unit

- No Electrode wear

- Minimum maintenance required

Superior Electrode Boiler INNOVATIONS

High-Pressure Steam

PARAT High-Pressure Boiler can contribute in reduction of NOx and CO2 emissions for large industrial companies, by replacing fossil fuel-fired boilers with clean Electrical steam production of up to 85 barg design pressure. This will be a major game changer to decarbonize high-capacity steam production.

Zero-Load

PARAT has developed a NEW solution to guarantee Zero-Load (patent pending) on our Electrode Boilers during standby. The boiler is consuming Zero power with the main switch still connected, being the superior solution for Grid Regulation.

Combined Hot Water & Steam

The PARAT Electrode boiler can NOW be delivered as a Combined Hot Water and Steam boiler in one unit (patent pending), with automatic switch of heat mode. This makes the boiler super flexible for any type of heating central in need of both hot water and steam.

Offshore Electrification

PARAT Halvorsen is playing an important role in electrification of the North Sea, and have received the first orders for 2x12 MW Johan Sverdrup and 2x17 MW (EX) Edvard Grieg project. Both projects will be electrified from shore power and reduce emissions significantly. PARAT will deliver complete turnkey skids, designed, manufactured and assembled in Flekkefjord, Norway. We are a qualified supplier of Power to Heat with excellent solutions for EX-Certified outdoor installations on Platforms and FPSO vessels.

Reduce installation time

PARAT Halvorsen does not only design and manufacture the boiler. Before the boiler is delivered, it can be tested by us with all turnkey equipment, primary circuit and PLC system installed to make sure that the end customer will have a smooth start-up and reduced installation time.

POWER to HEAT with PARAT Electrode Boiler

PARAT; boilers since 1920

Our Electrode Boiler has been designed and developed by our in-house engineers and manufactured in our workshop in Norway since 1990. PARAT Electrode Boilers are very reliable and are now the preferred Power to Heat solution worldwide. Thanks to our long experience, we delivered the first steam boilers designed for Grid Regulation in the World.

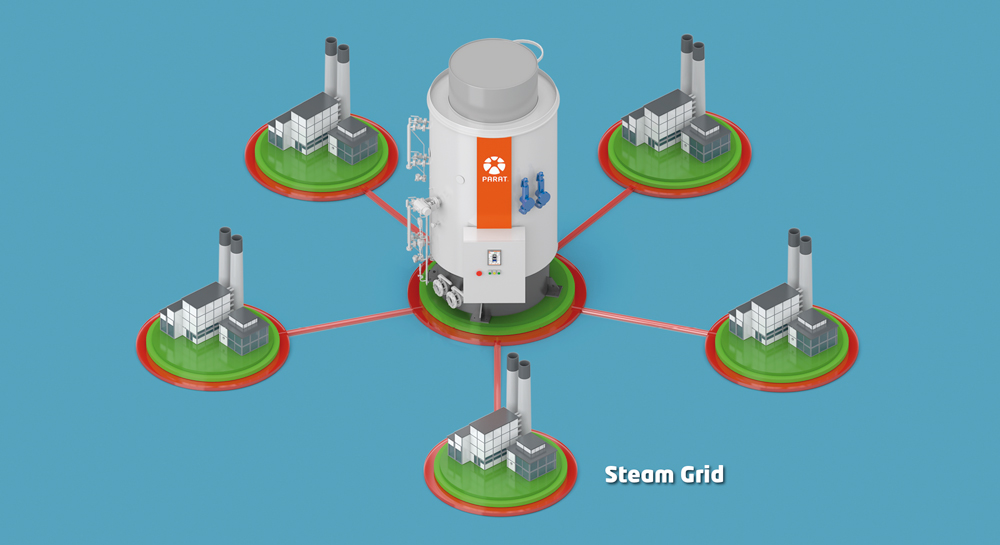

Hot water and Steam

The Electrode Boiler is delivered both in hot water and/or steam versions. Renewable energy can be used in steam grids and district heating networks. The Electrode Boiler is also a valuable backup boiler.

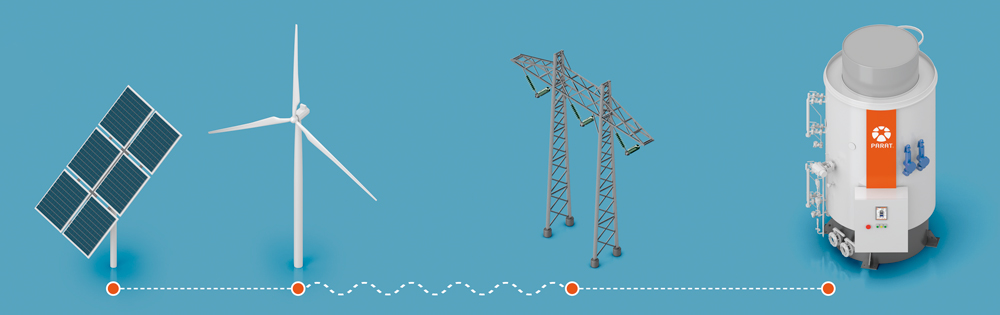

Grid Regulation

The growing production of renewable power from sun and wind gives more and more often excess power in the grid. This power must be used in order to stabilize the frequency of the current at 50 Hz. This is called grid frequency regulation.

Electrical grid regulation

Increasing power generation from wind and solar systems have created a demand for fast frequency regulation of the electrical power grids. The PARAT Electrode Boiler can be used for primary regulation with less than 30 seconds response time from minimum to full load. Converting electrical Power to Heat makes it possible to accumulate renewable energy in periods of overproduction. This allows the renewable energy sources to run continuously, and green power to replace fossil fuel.

The PARAT Electrode boiler gives the most compact and cost-efficient transformation of power to heat and is the superior solution for Grid Regulation.

PARAT Halvorsen designed the first fast Electrode Boiler, able to switch from standby mode to full load in 30 seconds.

Zero-Load

PARAT has developed a NEW solution to guarantee Zero-Load (patent pending) on our Electrode Boilers during standby. The boiler is consuming Zero power with the main switch still connected, being the superior solution for Grid Regulation.

Backup boiler

Since electrical power will be available as a cost competitive fuel in the future, the PARAT Electrode boiler will also be a valuable backup boiler in case of breakdown in the fuel-fired boilers or in the fuel distribution system. No other boiler types can be ready from cold condition to full load in 5 minutes.

Low power price

Even in countries where renewable energy is not yet widely used in power grids, the electrode boiler could be used in periods with low power prices e.g., during night-time and weekends.

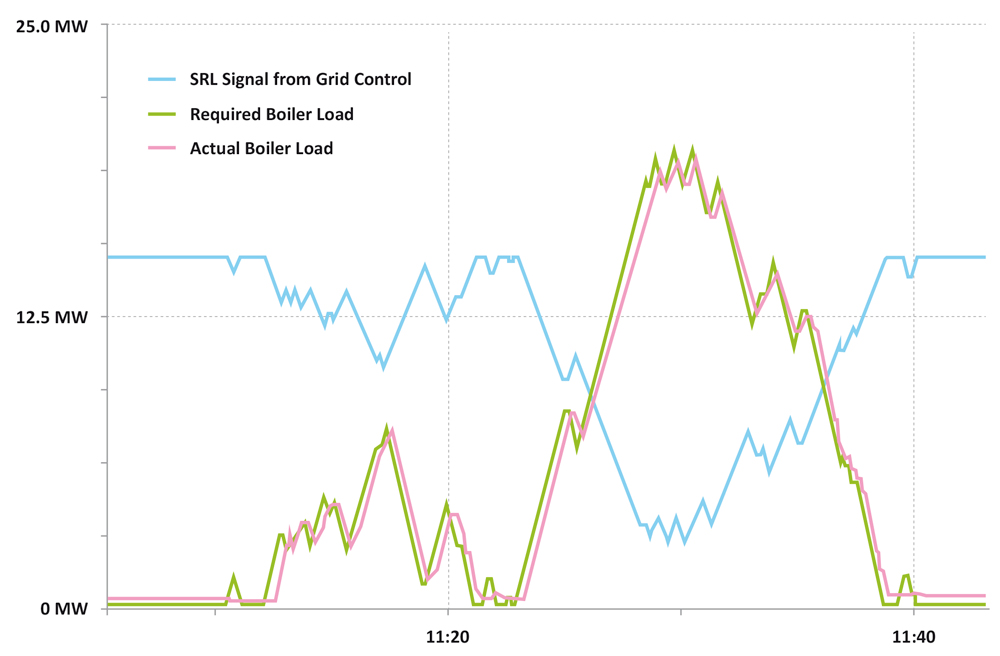

Typical SRL regulation curves at Infraserv Höchst, Frankfurt.

Steam Solutions

The PARAT Electrode Boiler is the world leading solution for High Voltage Electrode Steam Boilers. With steam pressure range of 6 - 85 barg and capacity up to 60 MW, you have the solutions for small and large capacity steam production. This is the perfect boiler to replace your fossil fuel steam boilers with clean electrical heat.

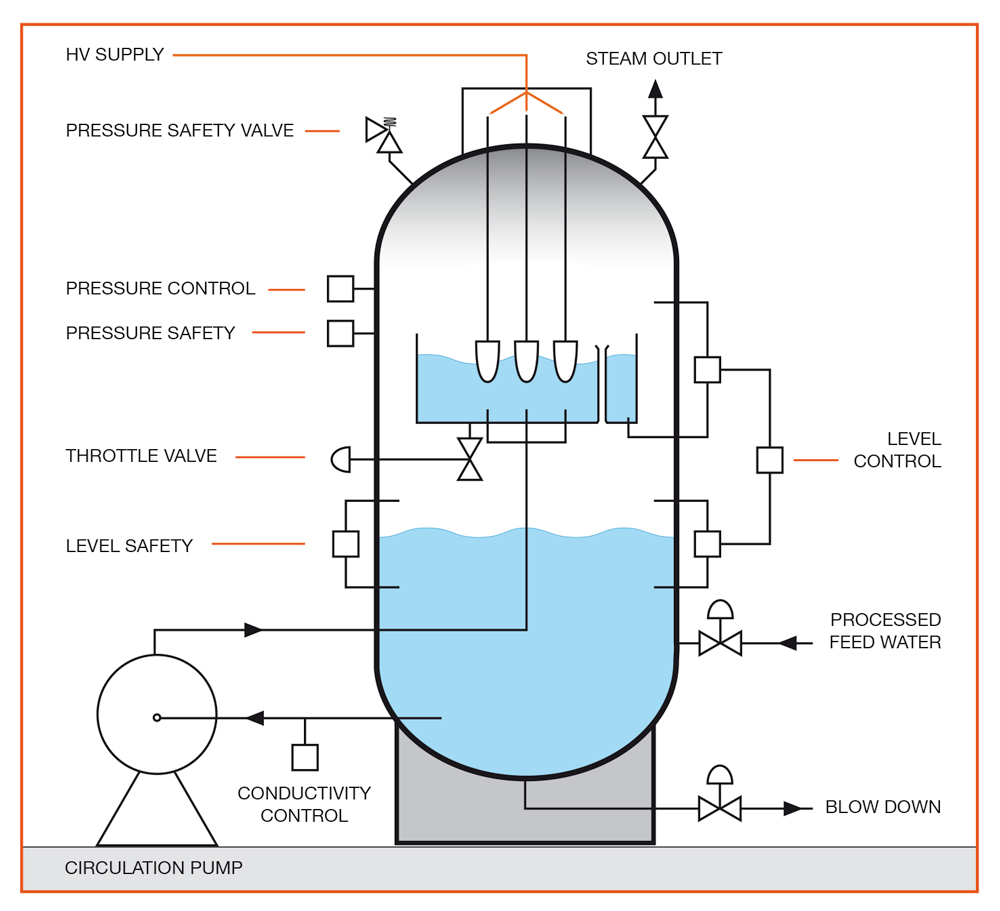

Steam is produced in the water between the electrodes. The internal circulation system brings water to the electrodes in a ratio 10:1 for the evaporation. The output is controlled by a throttle valve that regulates the level in the upper chamber.

Steam accumulates in the upper part of the pressure vessel and is released through the main steam valve. If the steam pressure increases over the setpoint, the power is automatically regulated down.

An important parameter related to optimal function of the boiler is the water conductivity. The conductivity is continuously monitored to ensure that the boiler gives the correct output. When the conductivty exceeds the selected setpoint automatic blowdown is initiated.

High-Pressure Steam

The Electrode Boiler can NOW be delivered as a High-Pressure Steam Boiler. We have developed the boiler with a design pressure of up to 85 barg and 30 MW per unit from 6-24 kV. This is the World's first modern High-Pressure Electrode Steam Boiler. By using this technology instead of fossil-fuel boilers, you will be able to reduce emissions significantly.

Combined Hot Water & Steam

The PARAT Electrode boiler can be delivered as a Combined Hot Water and Steam boiler in one unit (patent pending), with automatic switch of heat mode. This makes the boiler super flexible for every heating central with the need for both hot water and steam.

Super heating

Electrical steam superheaters can be delivered separately with low voltage supply.

Principle diagram of Electrode Boiler Steam generation system.

Principle diagram of Electrode Boiler Steam generation system.

Hot Water

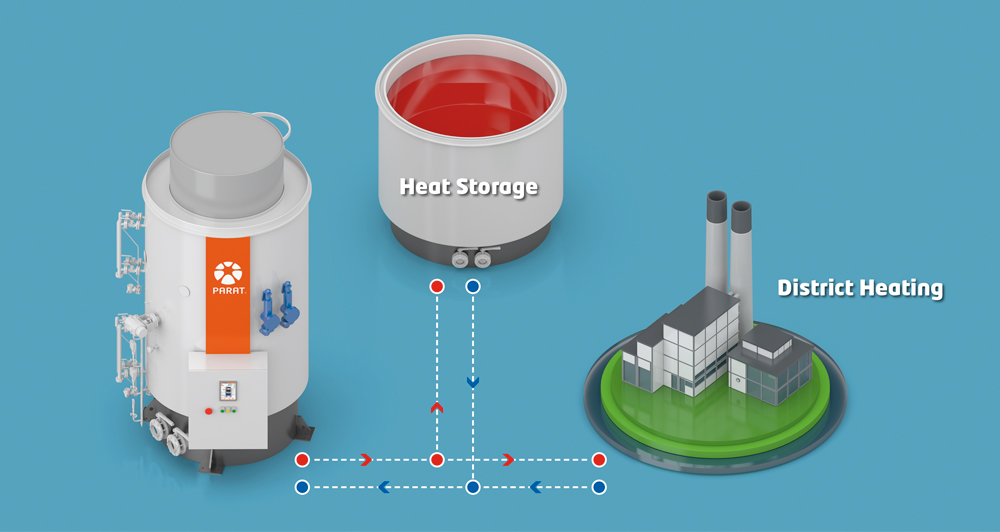

A district heating network will always have the possibility to receive excess power from renewable energy. This is the perfect boiler to replace your fossil fuel hot water boilers with clean electrical heat.

By installing a thermal storage tank, the capacity to receive large amounts of energy is available when getting the signal for grid regulation. Thereafter the energy can be released from the tank when the client needs the heat.

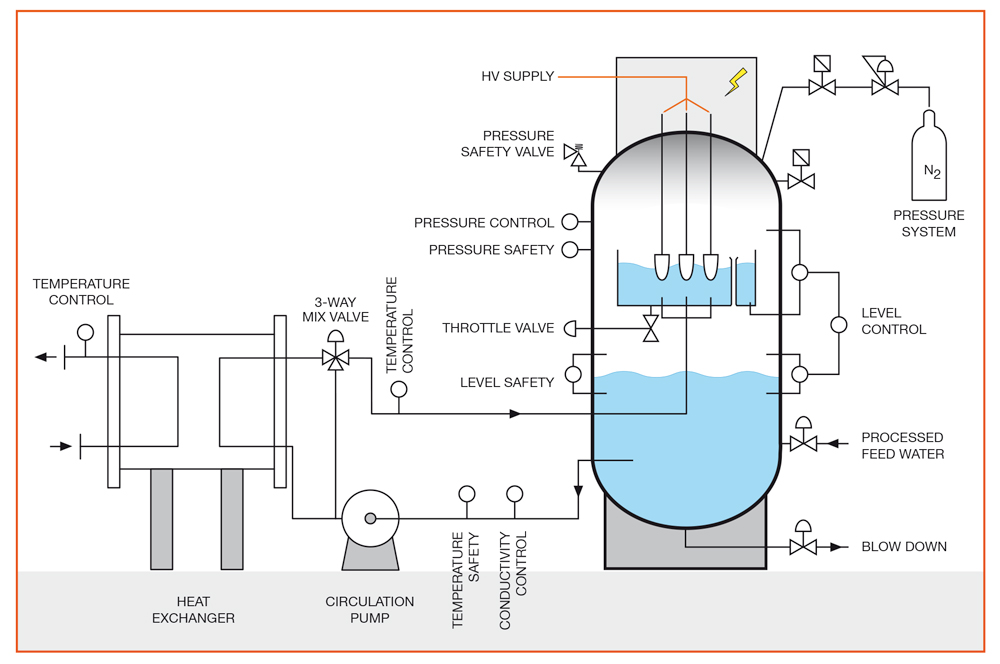

Hot water is generated by circulating the boiler water through the upper chamber where the electrodes are mounted. The boiler vessel is pressurized with nitrogen, and due to the relatively low water volume the boiler also acts as an expansion vessel.

If temperature delivered to the client exceeds the setpoint, power of the boiler is automatically decreased. The output is controlled by a throttle valve that regulates the level in the upper boiler chamber. An important parameter related to optimal function of the boiler is the water conductivity. Due to our optimal electrode design, water conductivity stays constant and thereby keeps water consumption at a minimum.

Our delivery can include piping, control valve and heat exchanger for heat supply to the district heating circuit.

Combined Hot Water & Steam

The PARAT Electrode boiler can be delivered as a Combined Hot Water and Steam boiler in one unit (patent pending), with automatic switch of heat mode. This makes the boiler super flexible for every heating central with the need for both hot water and steam.

Principle diagram of Electrode Boiler hot water system.

Principle diagram of Electrode Boiler hot water system.

Technical Specifications

Design codes

We deliver the boiler CE marked in accordance with PED/2014/68/EU with boiler code EN 12953. Other design codes on request. The Electrode Boiler is also available in EX version for installation in Zone 2 hazardous areas. The Medium Voltage connection cell is designed in accordance with EN 61936 for power installations.

Boiler principles

The boiler consists of an outer and inner container. Inside the inner container, which is electrically insulated from the outer shell, the electrodes are immersed. The boiler is designed for 6 - 24 kV. Heat is generated by ohmic resistance in the water between the electrodes. The boiler acts as a pure ohmic resistance in the main circuit. The water and the inner container form an insulated zero point in the star connection between the electrodes. PARAT has used this successful concept of electrodes since 1993. Thanks to the electrode geometry the current flux is so low that the electrodes are not worn out.

Control system

We have used our experience to develop a modern and robust boiler control system on the Siemens S7 Fail-safe PLC platform which is easy to use. The boiler is also available with PARAT remote monitoring system. This enables web-based remote monitoring of the boiler plant from anywhere in the world. This also includes online troubleshooting and upgrades of the control software from PARAT service centre in Norway. Instrumentation can be delivered as 1oo2 or 2oo3.

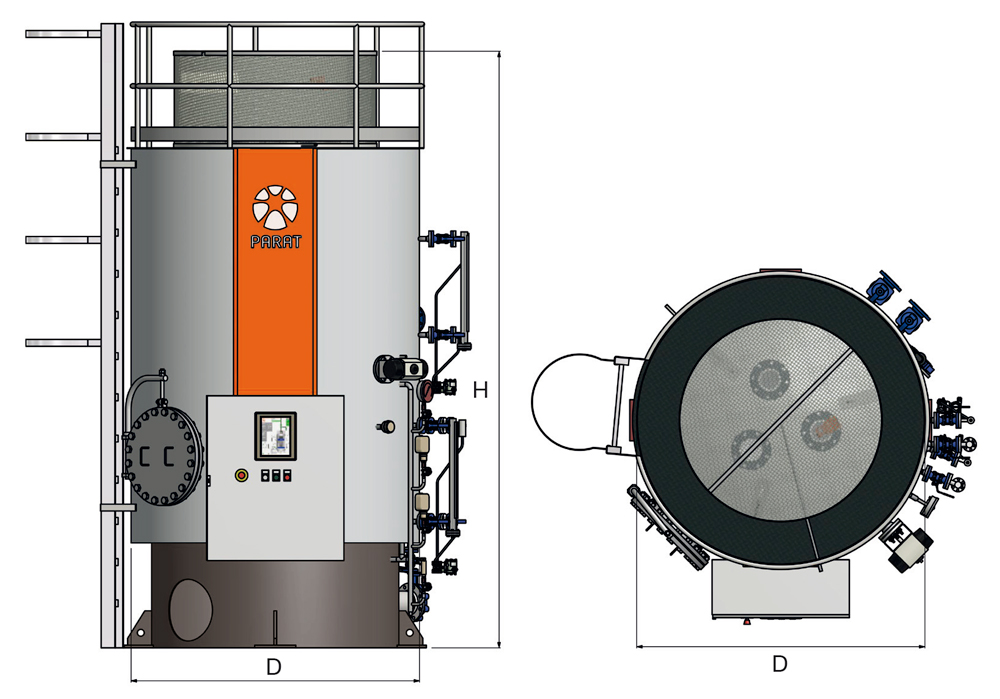

Dimensions

The Electrode Boiler is a very compact unit. Even a boiler with 60 MW capacity will normally fit into an existing boiler house. The boiler shell is insulated as standard with 2x75 mm Rockwool and cladded with powder coated aluminum sheets. Visual parts are painted.

Boiler outer dimensions given for electrode boilers including insulation mantle. We reserve the right to make changes:

Steam boiler

| Capacity (MW) | 0-5 | 0-15 | 0-30 | 0-45 | 0-60 |

| Steam (t/h) | 7,5 | 22,5 | 45 | 67,5 | 90 |

| D (mm) | 2.100 | 2.350 | 3.000 | 3.600 | 3.700 |

| H (mm)* | 4.800 | 5.800 | 6.700 | 7.000 | 7.400 |

| Transport weight (kg) | 6.500 | 8.000 | 13.500 | 20.000 | 23.000 |

| Operating weight (kg) | 8.500 | 11.000 | 21.500 | 34.000 | 38.000 |

| Test weight (kg) | 13.800 | 21.000 | 38.500 | 60.000 | 66.000 |

Weight data is given for 16 barg design pressure. Size based on 10 kV. Steam based on 100°C Feedwater temperature. Changes may occur.

* If circulation pumps are placed at same level as boiler, an additional height must be added for pump NPSH.

Hot water boiler

|

Capacity (MW) |

0-5 |

0-15 | 0-30 | 0-45 | 0-60 |

|

D (mm) |

2.100 | 2.350 | 2.700 | 3.100 | 3.500 |

|

H (mm) |

4.500 | 5.300 | 5.800 | 6.400 | 6.550 |

|

Transport weight (kg) |

4.500 | 6.000 | 9.500 | 15.000 | 16.000 |

|

Operating weight (kg) |

7.000 | 9.500 | 14.000 | 24.500 | 25.000 |

|

Test weight (kg) |

12.500 | 17.500 | 26.500 | 40.700 | 46.000 |

Weight data is given for 6 barg design pressure. Size based on 10 kV. Changes may occur.

See our Electrode Boiler introduction video.

PARAT Electrode Boiler EX-delivery to Edvard Grieg in the North Sea by Lundin Energy Norway.

PARAT IEH High Voltage Electrode boiler